Today, UPPF, an automotive PPF exporter, would like to share with you the process of car body surface paint with shallow scratches. If the paint layer is not scratched after inspection, the following repair methods can be used to repair it.

1. Car wash. The purpose of car washing is to remove pollutants, mud, etc. on the surface of the car body to avoid accidental damage.

2. Open the wax. The purpose of opening the wax is to ensure the light effect. For waxing, special waxing water is required

Remove the original waxy layer of the paint surface, while completely decomposing the waxy layer, without damaging the paint surface and plastic parts. To open the wax, you need to go through the steps of high-pressure washing of the body, spraying the wax water, wiping, cleaning, and drying.

3. Grinding and polishing the paint surface. Before the grinding and polishing of the paint surface, the appropriate polishing agent should be selected according to the condition and quality of the paint surface, such as thickness, hardness, wear resistance, etc. For shallow marks where the paint has been partially scratched, the grinding and polishing process can be divided into the following steps.

(1) Deep cut grinding. The purpose is to remove deep scratches on the paint surface, improve work efficiency and ensure polishing quality. The particle size of the abrasive for deep cutting should be selected to ensure that about 95% of the scratches on the paint surface can be removed. The particle size is generally 320-400 mesh. During the specific operation, first use a small towel to evenly spread the abrasive on the surface to be polished

On the surface, it is advisable for the operator to polish the area freely without moving his feet. Install the sponge polishing wheel on the polishing machine, dip it in water, keep the plane of the polishing wheel basically parallel to the paint surface to be polished (except for partial polishing), start the polishing machine, and set its speed at 1500~1800r/min. In order to keep the sponge polishing disc moist during polishing, clean water should be sprayed while polishing to reduce the temperature of the friction surface and avoid coking of the polishing wheel and damage to the finish due to excessive frictional heating. The grinding and polishing operation can be stopped when about 95% of the scratches are removed, and then the polished surface is rinsed with clean water, the residue is wiped off, and the polishing effect is checked.

(2) Center cut grinding. The main purpose of center cut grinding is to remove sand marks left by deep cuts. The particle size of the mid-cut abrasive should be 400-600 mesh. The specific operation method is the same as that of deep cutting. It should be noted that the center cutting polishing wheel should be replaced after a certain period of use.

(3) Micro cutting grinding. The main purpose of micro-cutting and grinding is to remove the fine sand marks left by the center cutting, and to perform surface polishing treatment to further improve the gloss of the paint surface. The particle size of the abrasive used for micro-cutting is generally above 600 mesh. The specific operation method is the same as above, and the polishing wheel for micro-cutting still needs to be replaced after a certain period of use.

(4) Polishing, the function of polishing is to remove the fine scratches left by grinding. The specific operation method is basically the same as that of grinding construction.

(5) Restore and brighten the paint surface. After the polishing operation, the shallow scratches on the paint surface have been basically eliminated, and some hairline scratches and spin marks remaining in the polishing operation can be treated by restoring the paint surface. When restoring the paint surface, apply the reducing agent evenly on the dry paint surface with a small piece of non-woven fabric, and then polish it with a non-woven cloth towel. After restoration, the paint surface is as bright as new, restoring the original style of the car body.

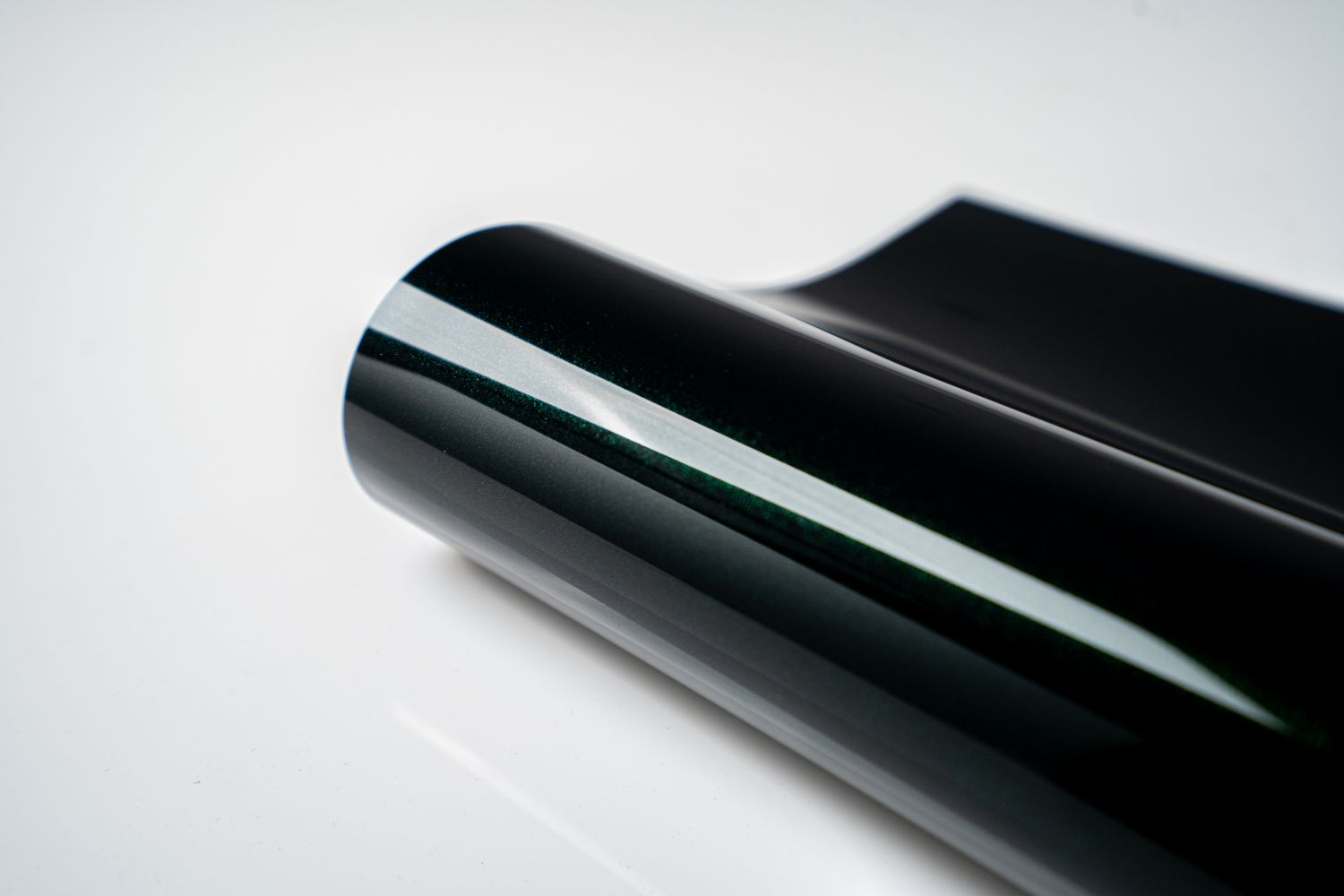

(6) Paint surface protection. Paint surface protection is achieved through the protection agent on the paint surface, and there are two types of paint surface protection agents: wax and enamel.

If you want to know more about PPF, welcome to consult UPPF, we will be happy to provide you with the most suitable customized solution.