UPPF, a supplier of automotive paint protection, told everyone that it is necessary to use automotive paint care materials when performing mirror treatment on automotive paint surfaces. At present, putty or polishing agent is generally used, and the material with the best mirror effect is her polishing agent.

In fact, polishing agent is also a kind of abrasive agent, which is an abrasive agent containing finer particles of friction materials. Polishing agents are divided into three types according to the size of friction material particles or effects: micro-polishing, medium-polishing and deep-polishing. Micro-polishing is used to remove very slight paint damage, generally refers to environmental pollution and acid erosion (bird droppings, fallen leaves, etc.) and deep throwing are mainly used to deal with different processes

Degree of hairline scratches. In addition, medium throw is better for transparent paint; while deep throw is more suitable for ordinary paint.

In general, polishing agents and reducing agents are the same type of material as far as the friction materials contained are concerned. The main difference between the two is that the reducing agent contains glazing material (glazing agent or wax), while the polishing agent does not contain glazing material, and it does not contain glazing material. It is very important to produce a "mirror effect" on the car paint surface .

To improve the glossiness of car paint, in order to achieve "mirror effect", the main ways to polish are:

(1) Rely on the power of grinding and friction materials to remove the fine scratches;

(2) Rely on the effect of wax, after polishing to a certain extent, rely on the luster of wax to make up for the defects of polishing;

(3) By chemical reaction, that is, the chemical reaction produced by the polishing agent by adjusting the speed of the polishing machine.

The first two methods are commonly used by ordinary people. The main reason is that ordinary people are different from the speed of the polishing machine, the material of the polishing head (all wool material, blended material, sponge material and cotton material, etc.), the structure of the paint and the efficacy of the polishing agent. The relationship between them is not well understood and experienced, so the requirements for polishing are not high. Because it doesn't matter if it is not too shiny, it will be very shiny after applying the wax. But this kind of light is a virtual light, it does not achieve the final mirror effect, and the gloss has no depth. And it stays for a short time, because its luster is not from the lacquer, but from the wax. No matter how good the wax is, its luster can only last for three months at best. If the luster of the wax is gone, the luster of the car paint will also be gone.

Therefore, the method that can really produce a good "mirror effect" should be the third method, that is, use the heat brought by the speed of the polishing machine to generate an energy and a chemical reaction between the car paint and the polishing agent to eliminate fine scratches , let the car paint show its own luster, and then apply polish wax to make the car even better. The brighter the car paint, the longer the luster of the wax will last, but when using this method, the difficulty and skill is to find out what kind of paint to use, what kind of polishing agent to use, what kind of polishing head to use, and what kind of polishing head to use. What speed, how much pressure to give, how many times the machine should go back and forth, etc.

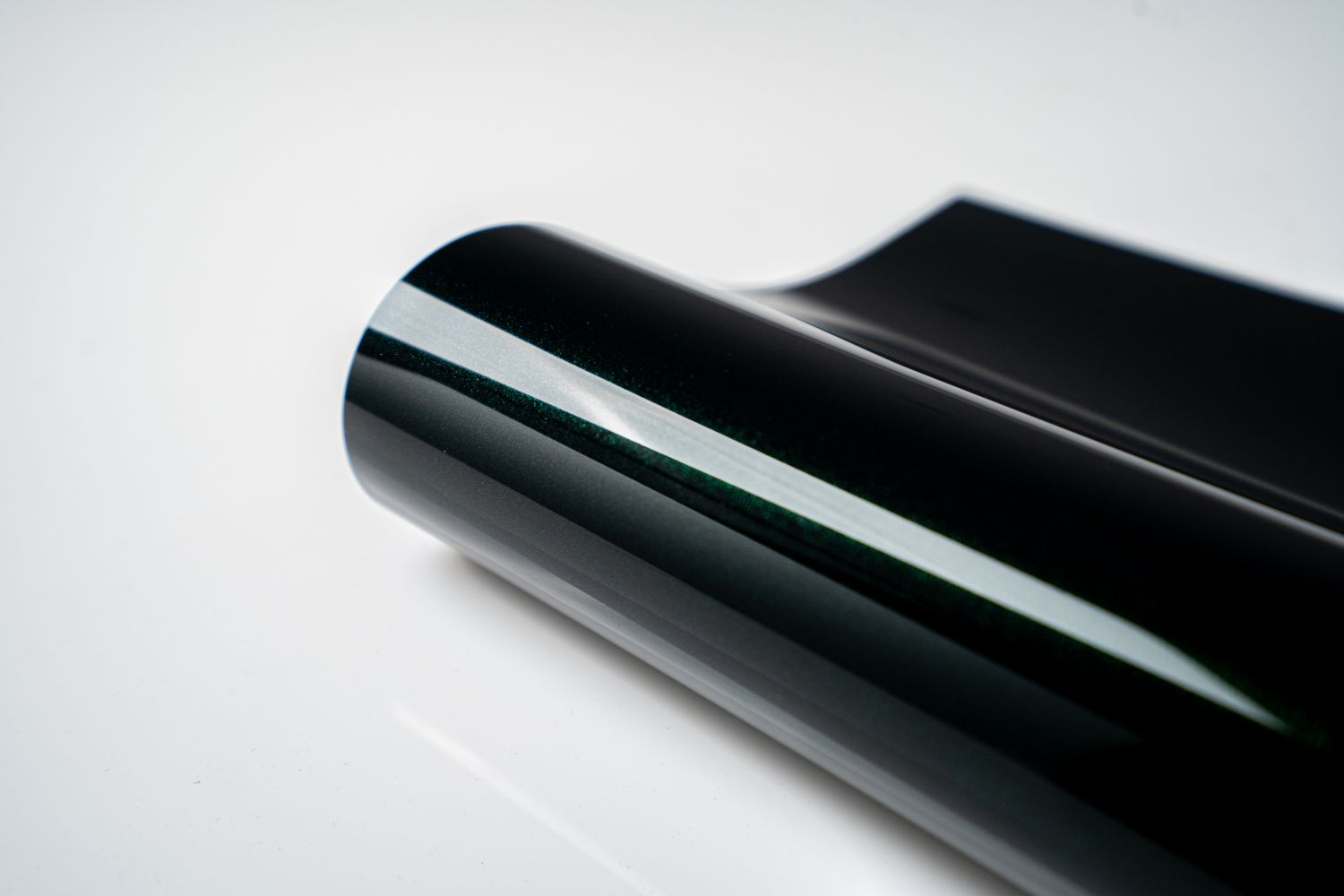

It is a reliable product among the existing car paint protection films supplied by UPPF. Putting a paint protection film on your car is a wise choice for effective care of your car!